What makes CHICKEN Australia’s favourite meat?

Research tells us that Australian consumers select chicken meat for its value, taste, nutrition and versatility but there are even more reasons to enjoy Australia’s favourite meat.

Chicken has the lowest carbon footprint of any meat

Australian chickens are not given hormones or steroids

Meat chickens in Australia are never raised in cages

More than 99% of chicken meat consumed in Australia is grown in Australia

Cooked chicken is an excellent source of protein as well as key vitamins and minerals

No antibiotics that are critically important in human medicine are used routinely in chicken production

How is CHICKEN produced in Australia?

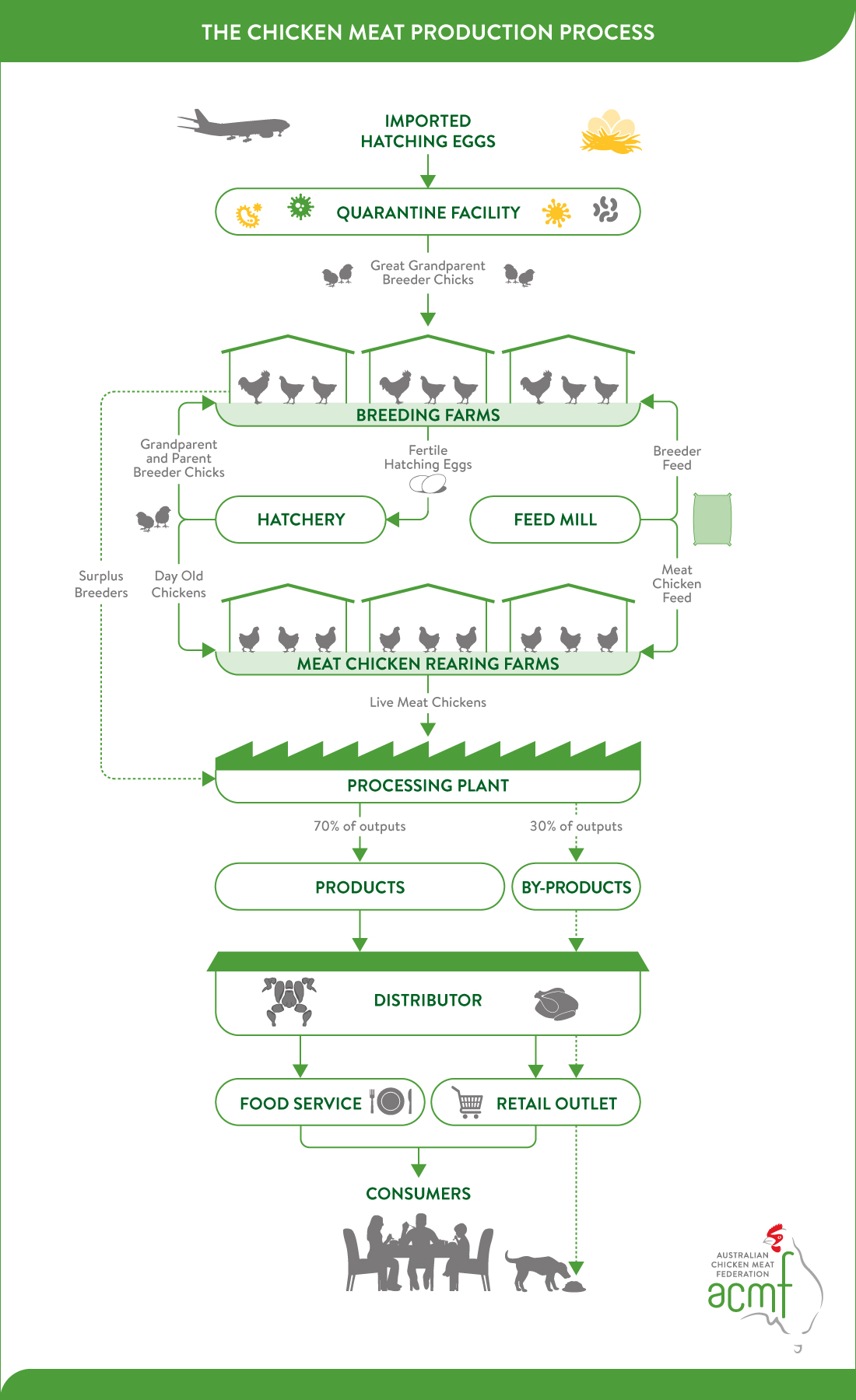

IMPORTED HATCHING EGGS

To ensure Australia has access to the world’s best poultry stock, the industry regularly imports eggs from international breeders. These eggs, which have been bred for a range of traits, are imported as fertile hatching eggs and become ‘Great Grandparents’ to today’s meat chickens.

QUARANTINE FACILITY

Imported eggs are incubated and hatched in a quarantine facility and kept safe until they are nine weeks old. Throughout their time in the quarantine facility, they are monitored closely and tested to confirm that they are free from disease and safe to be released into the general poultry population to breed.

BREEDING FARMS

On arrival at the breeder farm, day-old breeder chicks are placed on the floor of a climate-controlled, well-ventilated rearing barn with easy access to feed and water. All Australian meat chickens and meat breeders are raised in barns, not cages. As breeder flocks approach sexual maturity, they are transferred to laying barns. The eggs from these flocks are collected and sent to a hatchery.

HATCHERY

On arrival at the hatchery, eggs are fumigated to kill any bacteria or viruses on the eggshell and held in a cooled storage room until ready to commence the 21-day incubation process, which involves ‘setting’ and ‘hatching’.

In the setter stage, eggs are housed in a machine called a setter for 18 days. These machines mimic the natural conditions a hen would provide for proper development of the chicken embryo inside the egg, including controlling temperature and humidity and turning the eggs hourly to make sure the embryo doesn’t stick to the inside of the eggshell.

In the second stage of the process, eggs are transferred from the setter to a piece of equipment called a hatcher. The hatcher provides similar conditions to the setters but a slightly higher temperature, encouraging development and stimulating hatching. The second hatching stage takes three days.

After hatching, the chicks are graded and checked that they are fit enough to go out to the farm. They may be vaccinated for some infectious poultry diseases, then counted and dispatched to breeding or chicken-rearing farms.

When a chick hatches it absorbs into its abdomen what remains of the yolk, giving it nutrients which last until it is delivered to a farm where it will be reared.

FEED MILL

Feed Mills are responsible for mixing, milling, weighing, pelleting and delivering carefully developed feed for meat chickens and breeders. Because of the vertically integrated nature of Australia’s meat chicken industry, the majority of Australia’s feed mills are owned by chicken processing companies.

MEAT CHICKEN REARING FARMS

A meat chicken farm will comprise several barns, along with other farm infrastructure such as feed silos, sheds and a manager’s house.

Most commercial meat chickens are grown on the floor of large poultry barns, and none are in cages. The floor of the barn is covered in an absorbent bedding material. Generally, feed and fresh water are available to the chickens 24 hours a day.

Meat chickens are reared for a period of between 30 and 65 days before being processed.

PROCESSING PLANT

This is where the birds are processed, and the chicken meat is cut up, packed, packaged and stored ready for transport or further processing.

Processing plants are very large, highly mechanised operations. Australia’s largest poultry processing establishment processes more than 100 million chickens per year – that’s 2 million chickens per week.

PRODUCT PLANT

Once the chickens have been processed, they are either packaged and chilled, or processed further into a variety of products for sale to distributors or direct to retailers and restaurants, before being enjoyed by consumers.

Around 70 per cent of the chicken is produced into meat products. Being a low-waste industry, the remaining 30 per cent, which includes bones, feathers etc are used to create products such as pet food.

CONSUMER

Australians currently consume around 50kg per person of chicken each year, making chicken Australia’s favourite meat.

Chicken meat and its by-products are also used in other applications, for example in pet foods.